On a vessel, everybody needs to know how to do everything. If one member of the crew is not there to take care of something, another person must be able to complete the task. On most boats, electricity comes from the generator and it runs on fuel. To keep running the generator requires its oil to be changed every one hundred running hours. This process is not as easy as just buying some oil and filling a tank, but needs an assortment of supplies and it takes many steps to complete this job. First, you must gather the appropriate supplies. This includes:

- Motor oil of proper viscosity,

- 5 gallon bucket,

- Funnel,

- New generator filter,

- Garden hose,

- Paper towels; and

- 1 ½″ thick 3′ long rubber hose.

Before you start, it is a good idea to have paper towels, or special oil absorbent cloths, set aside to wipe down spilled oil or to clean the area that you are working in.

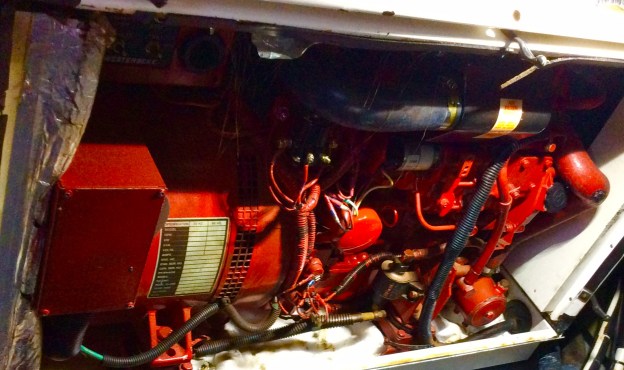

Once in the engine room, open the generator selector valve and attach the rubber hose to the pump discharge fitting. Place the 5 gallon bucket at the end of the rubber hose that is not being used. Flip the pump switch to drain position and pump the dirty oil into the bucket.

Ryan pumping the old oil out of the generator.

Next, disconnect the oil hose pump, wipe off any residual oil, and stow it away.

Ryan disconnecting the oil pump hose

Coil the hose, wipe it clean & stow it away

Stowing the hose away

Next, locate and unscrew the old oil filter. Clean the threads of the oil filter with paper towels, and securely dispose of any residual oil in the old oil filter.

Ryan pointing to the old oil filter

Remove the old oil filter

Drain oil out of old oil filter into secure receptacle

Securely dispose of old oil filter

Before installing the new oil filter wipe clean oil on the O-ring of it.

Dip finger in oil to lube ring of new oil filter

Lube outer ring of new filter with clean oil

After wiping clean oil on the new filter, screw it in where the old oil filter was and hand tighten.

Secure new oil filter. Tighten with hand grip.

Next, disconnect the rubber hose from the pump discharge fitting. Pop the cap off where the oil is to be inserted into the generator and insert a funnel.

With funnel securely in oil input valve, pour in new diesel oil

Carefully, pick up the five quart container with clean oil and pour approximately 4 quarts through the funnel. Be sure to pour it slowly or it will overflow over the funnel making a mess.

With funnel secure in oil input valve, add Diesel Oil

After adding approximately four (4) quarts of oil, take out the dip stick to check its level.

Ryan checking the dip stick oil level

If the dip stick does not reflect the amount of oil inserted into the generator, you should probably check for a leak or other malfunction that could cause this. If the dip stick indicates it needs more oil, then poor one more quart of oil through funnel before placing the cap back on.

Add another quart of oil

Since this is a messy job, now would be the time to wipe down any spilled oil with paper towels, or oil absorbent cloths and to securely dispose of all of the garbage from this project.

Use oil absorbent cloth to clean any drips and spills

Cleaning the engine room bilge

It is also helpful to spray down the engine room with a garden hose to further clean up the mess. Once everything is closed back up, you should run the generator with no load to check for leaks. If there are not any leaks seal up the generator cover.

Close up and secure sound shield covering on generator

Secure sound and fire proof generator shield

Finally, so you know when to change the oil next, log the generator’s hours in your captain’s log.